Magnetic Couplings

Magnetic Couplings consist of an outer and inner drive and they do not touch one another. A coupling works via the non-contact transfer of power which means the magnetic solution, in contrast to the traditional, does not experience any wear. Therefore, the Magnetic Couplings are maintenance-free.

Magnetic Couplings consist of an outer and inner drive and they do not touch one another. A coupling works via the non-contact transfer of power which means the magnetic solution, in contrast to the traditional, does not experience any wear. Therefore, the Magnetic Couplings are maintenance-free.

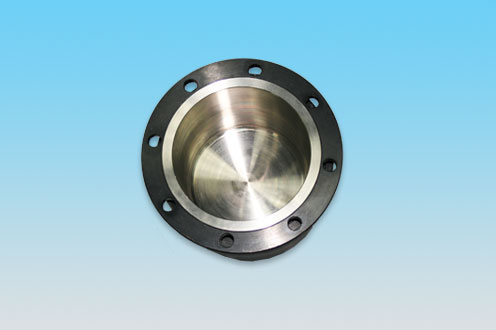

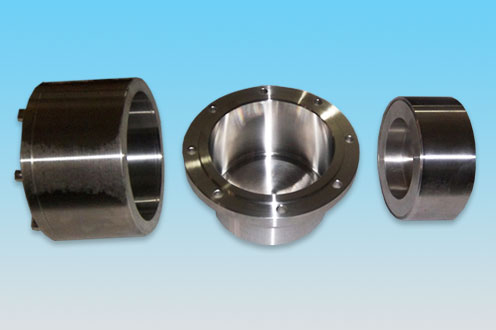

It's possible to place a can between the two rotating units so that two different media can be kept separate. With the hermetic enclosure of the coupling in a stainless steel housing, corrosion is avoided and the coupling can operate directly as a wet runner in different liquids and environments. The outer drive is normally connected to the drive unit and the inner drive is, for example, connected to a pump.

Magnetic Couplings are also called torque couplings because they can transfer a certain maximum mechanical torque through the air. If the torque exceeds this maximum value, the coupling will "slip", which means that the rotational speed between the two coupled units is no longer the same. This prevents wear and tear and the Magnetic Couplings provides a built-in safety feature that protects against damage.

There are two main types of couplings. One type has a radial design that is similar to an ordinary electric motor, while the other is axially oriented so that it can transfer forces through a surface.

Contact us or give us a call today with your ideas, challenges, and questions.